Industries with strict hygiene requirements, such as pharmaceuticals, life science and food, ZHICE provide precise and efficient solutions to safeguard quality and stay compliance.

Product safety, compliance and data integrity

In food and pharmaceutical production, strict safety guidelines and quality standards must be followed and the production process must be consistent and reliable. This guarantees the safety of food and pharmaceuticals and ensures that the final product quality is as high as possible, which is essential to maintaining the safety of the end consumer.

Sterilization is a critical step in the manufacturing process that kills any bacteria and helps ensure that drugs, packaging, utensils, clothing, etc. are safe to use.

Temperature Distribution and Heat Penetration

The most common method of sterilization is heat. Temperature distribution refers to how evenly heat is spread throughout the sterilization chamber/autoclave. Proper heat distribution ensures that every part of the chamber reaches the required temperature for sterilization. Uneven heat distribution, can result in certain areas not achieving the necessary conditions (cold spot), leading to incomplete sterilization. Achieving uniform temperature throughout the sterilizer is essential for effective sterilization. Another parameters that we pay attention to is heat penetration. It indicates how effectively heat moves through the product or materials being sterilized. Thus the sensor/logger is placed inside the package to ensure that not only the surface but also the innermost parts of the product reach the required temperature for a sufficient period to achieve sterilization.

A better way to validate sterilization process

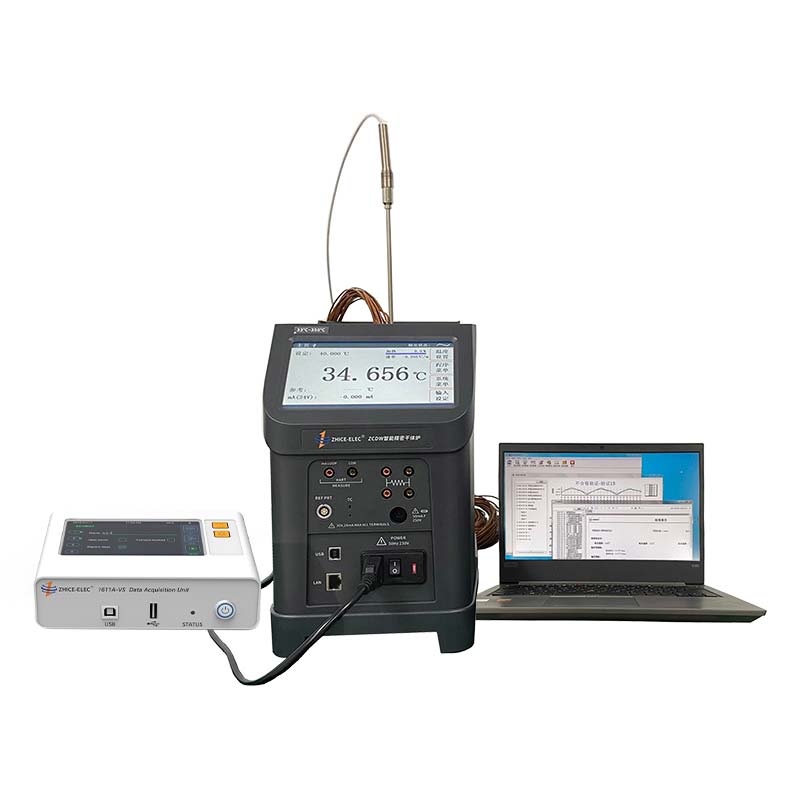

Many of the world’s leading pharmaceutical, life sciences and food companies rely on ZHICE temperature validation system, designed to help users stay compliance according to industry regulations, such as GMP and FDA.

Our solutions have flexible configurations and can be selected based on the sterilizer situation and laboratory capabilities. ZHICE-ELEC not only provide temperature sensors, reading devices and validation software, but also pre- and post-calibration temperature field. The complete set of products is developed and manufactured by ZHICE to ensure overall equipment performance, cost effectiveness and guaranteed after-sales.

--

Please Read On, Stay Posted, Subscribe, And We Welcome You To Tell Us What You Think.

Copyright @ 2024 Hefei Zhice Electronics Co., Ltd.. All Rights Reserved. Sitemap / Blog / XML / Privacy Policy

Network Supported

Network Supported